Do you remember the Kodak Q-Lab System? In case you were a commercial photographer in the 1990’s you probably do. To certified photographic laboratories Kodak offered this Monitoring Service for E6 Film Processing. It should guarantee photographers the same process quality, regardless to which lab they handed over their films.

This was obviously a smart marketing move which more or less obliged the lab owner to work with Kodak chemicals. It certainly had value to photographers though. To fashion and sports photographers it wasn’t unusual to shoot hundreds of rolls of film at the other side of the globe. Far away from their trusted lab. The E6 process for colour positive film is pretty critical. Sloppy processing leads to noticeable deviations in colour, contrast and density.

Q-Lab aimed to make the process quality measurable. A certified lab was obliged to send an employee to Kodak for training. They had to invest in a kit containing reagents, a densitometer and some software. The lab itself was evaluated by a Kodak Technical Sales Rep. If all requirements had been fulfilled, that same rep would come back a few weeks later to hand over a cake and a Q-Lab sign to display at the entrance.

To monitor the process Kodak provided pre-exposed film strips. The ones for daily use were supplied on a 30m roll. The lab technician had to tear one off in the dark to process at the beginning, end and halfway the working day. The strip’s colour and grey patches were measured at the densitometer and compared to the aims. In case it was out of tolerance, the chemical test kit had to be used. Samples of the First Developer, Reversal and Colour Developer could be mixed with reagents which enabled a visual analysis of the chemicals. Needless to say that it came with a reference guide suggesting solutions for every possible deviation. Things like a minimal adjustment to the first rinse’s temperature or adding some sodium hydroxide to the colour developer.

This all seems ages ago. In nowaday’s archival/cultural heritage photography though there’s also a strong need to make quality measurable. Apart from the chemicals it bears a more than superficial similarity to what Kodak offered to the photo finishing industry. The FADGI and METAMORFOZE initiatives strive to give clear guidelines that can be objectively verified. Admittedly, they go a step beyond the Q Lab procedure.

Quantifying the digitisation process’ Quality

While striving for excellence is honourable, not all materials require the same amount of precision. Digitizing a famous artist’s historical handwriting requires a higher quality level than the archives of a newspaper. In both cases text recognition is equally important. The handwriting’s file however needs to show the structure of the paper and have a tonal range resembling the original as close as possible. Qualities you may forgo when digitizing the paper. Therefore both FADGI and METAMORFOZE offer various quality levels. FADGI uses stars to distinguish its levels. FADGI**** is the highest obtainable quality with today’s technology. METAMORFOZE has three quality levels, which roughly correspondent with FADGI two, three and four stars. The FADGI one-star level has no equivalent in METAMORFOZE. It’s for localisation only, like a thumbnail in a library.

In Europe the ISO Standard 19264-1 is widely accepted. It’s distilled from the FADGI and METAMORFOZE norms. Currently it doesn’t provide guidelines for translucent materials, these will be added though.

METAMORFOZE was initiated by the Dutch National Library and the Dutch National Archives. Therefore it focuses solely on the digitization of printed materials. Guidelines for translucent materials are missing. The Federal Agencies Digitization Guidelines Initiative (FADGI) has a broader scope. For that reason we’ll look at FADGI below.

Requirements

FADGI provides guidelines for the digitization of a multitude of materials, ranging from rare bound volumes to photographic transparencies to radiographic X-Ray film. For all these materials it quantifies:

- File Format

- Resolution

- Bit Depth

- Color Space

- Tone Response

- White Balance Accuracy

- Illumination Uniformity

- Color Accuracy

- Color Channel Misregistration

- MTF Requirements

- Scale Accuracy

- Maximum Sharpening

- Maximum Noise

Resolution is an easy one; it can be calculated and doesn’t need any specific measurment tools nor software. For a FADGI**** digitization of photographic negatives from 35mm through 4×5” a resolution of 4000 ppi is required. Photographic prints require 600 ppi to adher to the same standard.

The resolution of a “Small Medium Format” camera like the Fujifilm GFX-100 or Hasselblad X2D easily exceeds the Fadgi**** requirements to digitise 35mm film. For larger film formats only the sensor in a Phase One IQ4 back meets that standard. It goes without saying that the best optics and lighting are needed to adhere to the other requirements.

Measurement is crucial

Certification for FADGI compliance requires objective testing methods. These are outlined in the Digital Imaging Conformance Evaluation program (DICE). A DICE procedure always requires:

- Reflective and/or transmisive image targets

- Software to analyse the captured targets

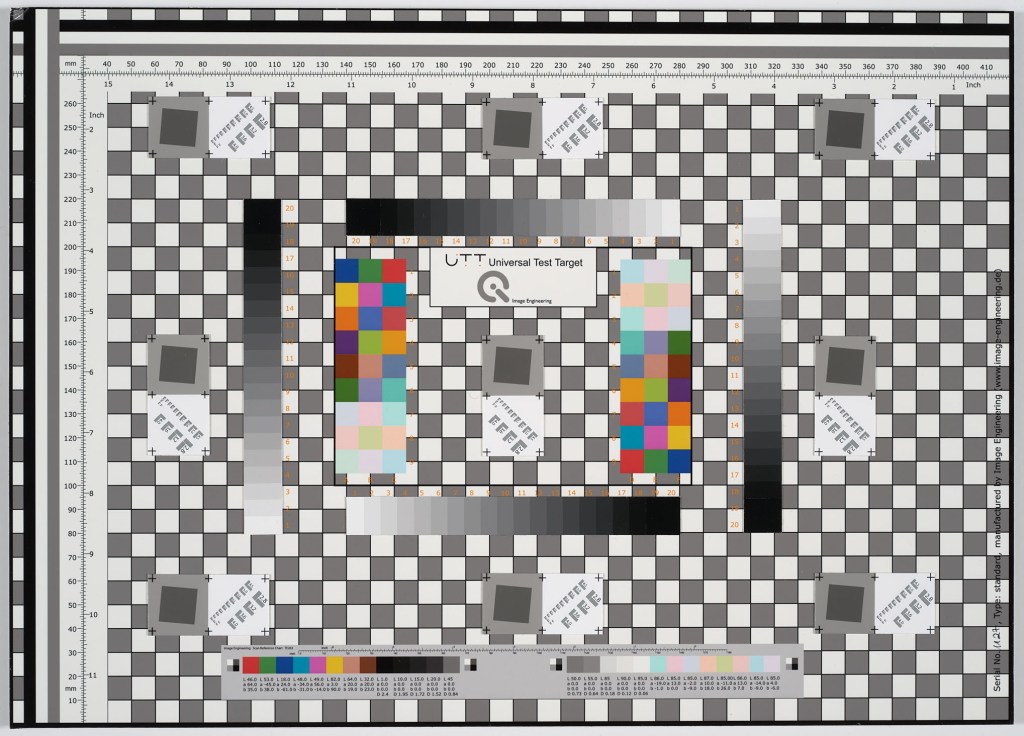

A Device Level Target (DLT) takes the place of the object that’s to be digititzed and fills the best part of the frame. It includes color and grey patches, a ruler and patches to evaluate sharpness and to detect aberations. A DLT is typically captured at the beginning and end of a batch.

An Object Level Target (OLT) basically features the same patches as a DLT but is small enough to be captured alongside every object. Whereas a DLT is easier to evaluate thanks to its larger size, some institutions oblige their photographers to include an OLT in every capture.

Universal Test Target (UTT) is a generic term which can refer to both DLT and OLT.

Software such as provided by Image Engineering and Image Science Associates enables objective analysis of DLT and OLT captures. Alternatively you may upload the file to outsource the analysis. Phase One offers their free NimbusQA service. It analyses an uploaded file within minutes. The detailed report not only gives a score, but also tells you where the capture may fall short.

As outlined above, FADGI, METAMORFOZE and ISO 19264-1 help us to quantify most of the parameters of the digitization process. It also pays attention to Best Practices. Although less measurable, these are equally important. In general there’s a lot of knowledge exchange between people working in this industry, which makes Best Practice more than just a hollow phrase. It’s very well possible to create FADGI compliant images without adhering to technical recommendations and best practices. However, it may become a lot easier to maintain an efficient and repeatable workflow when you do. Products like our RPS copy stands and film stage provide the necessary stable platforms. A stand like the MST can mean the same in the digitization proces of works of art that are too large for flat lays.